Fusion-bonded epoxy coatings are epoxy powder coatings that are commonly used to protect steel pipes, valves and other materials used in harsh environments.

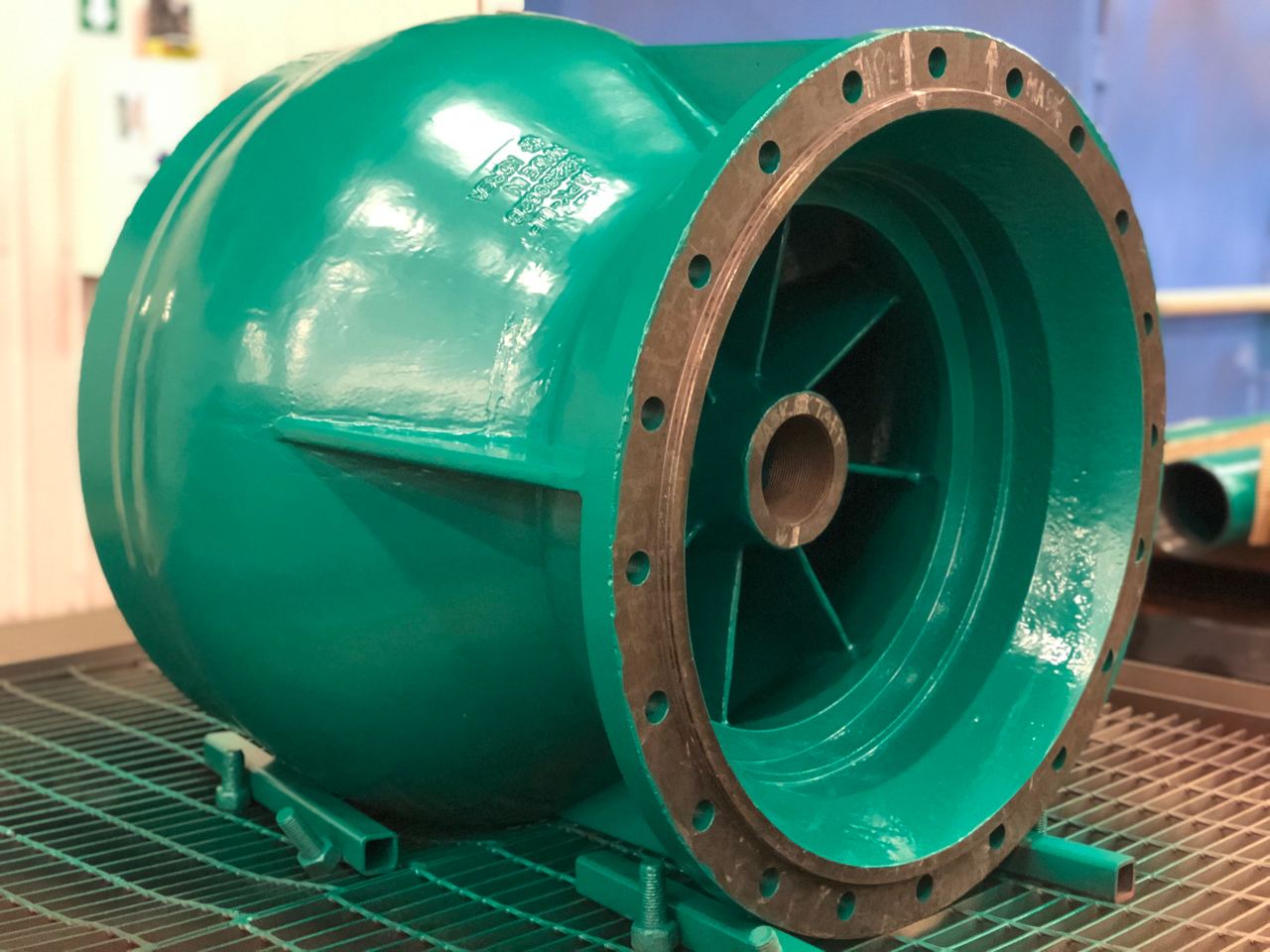

Our premier epoxy powder coating known as System 8 turns to liquid when applied on pre-heated parts. Once cured, a tough uniform protective layer is created, providing resistance to harsh environments seen in wastewater, corrosive soil, hydrocarbons, harsh chemicals and seawater.

Which Industries Use IPC Epoxy Powder Coatings?

FBE coatings have quickly become the gold standard across a variety of industries. This is thanks to their ability to protect against corrosion which can dramatically increase the service life of equipment and reduce costs and project delays. While there are several industries that make use of epoxy powder coatings, oil and gas and municipal and potable water agencies have made fusion-bonded epoxy coatings an integral part of their strategy to protect their equipment from the damaging effects of corrosion.

Also Read: 3M Scotchkote 134 – Fusion Bonded Epoxy

Oil & Gas – Numerous Canadian and international oil and gas companies choose our fusion-bonded epoxy powder coatings for their offshore and onshore projects.

Our IPC System 8 offers superior corrosion protection and is suitable for different pipe-laying methods and soil conditions. The FBE coating gets applied inside and outside the pipe and is a highly effective method of protecting it from corrosive chemicals and environments.

Municipal & Potable Water: Our fusion-bonded epoxy powder coating offers amazing corrosion protection and is environmentally friendly because it includes no solvents. When you coat anything that transports drinking water, you need to be extremely careful that the pipes being coated will not leech anything into the water that could be dangerous to people drinking it.

The lack of solvents in our FBE coatings makes it a fantastic choice for the municipal water industry. In fact, our fusion-bonded epoxy coatings exceed most requirements for potable water and the protection it offers in harsh environments is unmatched.

How Are Fusion-Bonded Epoxy Powder Coatings Applied?

After we have cleaned the equipment, we do a thorough inspection to make sure it is ready for coating. Then we spray the fusion bond epoxy on the surface. Once the epoxy powder melts and dries, the barrier is formed. This bonding process provides amazing protection for things such as valves, pumps, sewer pipes, hydrants and more.

What are the Benefits of IPC Fusion-Bonded Epoxy Powder Coatings?

Chemically Resistant – Our fusion-bonded epoxy powder coatings offer excellent resistance to CO₂, H₂S, CH₄ and crude oil and brine.

Corrosion Resistant – Epoxy powder coatings are especially useful for coating the inside of a pipe, pumps, or other fabrications where a smooth corrosion-resistant coating is required.

Tested and Certified – Not only are these powder coatings NSF/ANSI certified they also meet the requirements of AWWA Standard C213 and C550 and have been approved for use by the National Sanitation Foundation guidelines that regulate drinking water supplies.

Various Applications – IPC epoxy powder coatings can be used on a variety of equipment and production pieces including steel pipes, fittings, valves, couplers, pumps, extension springs, and more.

Suitable For Water Environments – Our fusion-bonded epoxy powder coatings are commonly used in municipal water projects, protecting potable water infrastructure, seawater intakes, and ancillary equipment protection.

Environmentally Friendly – FBE coatings can be applied without emitting any harmful substances making it a sensible option for companies who prioritize sustainability.

Need Engineering or Product Assistance on Your Next Project?

At IPC, we have established a decades-long reputation for being the top coating applicator on some of the biggest projects around the world.

Our in-house professional engineers are APEGA and AMPP Certified. They can provide invaluable insight and support to your team regarding the best coatings for your upcoming or current project.

Contact our engineering team and learn more about the fusion-bonded epoxy powder coating products we offer and which one is best suited for your industry.