Since 1978, Integrated Protective Coatings (IPC) has been a leader in making top-quality coatings to fight corrosion and erosion.

Our dedication to quality and innovation has made us the top coatings maker in Western Canada.

We are trusted by customers who want the best protection for their valuable assets.

In this blog post, we explore our sandblasting services and process, which is essential for our metal finishing services.

It’s a crucial step in preparing surfaces flawlessly and ensuring coatings adhere exceptionally well.

Understanding the ins and outs of sandblasting gives you insight into how IPC remains committed to providing the highest quality performance for our valued customers.

Sandblasting Services: Surface Pre-Treatment

Sandblasting is essential for enhancing surface quality before adding protective coatings like electroless nickel or fluoropolymeric deposits.

At IPC, we excel in precise sandblasting services designed to:

— Remove paint, rust, and other impurities that affect surface integrity.

— Prepare metal surfaces to ensure excellent adhesion of future coatings.

— Attain the smoothness required for flawless finishes meeting the highest standards of quality and aesthetics

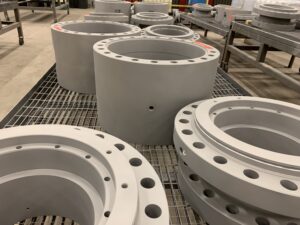

After Thermal Cleaning

After Sandblasting

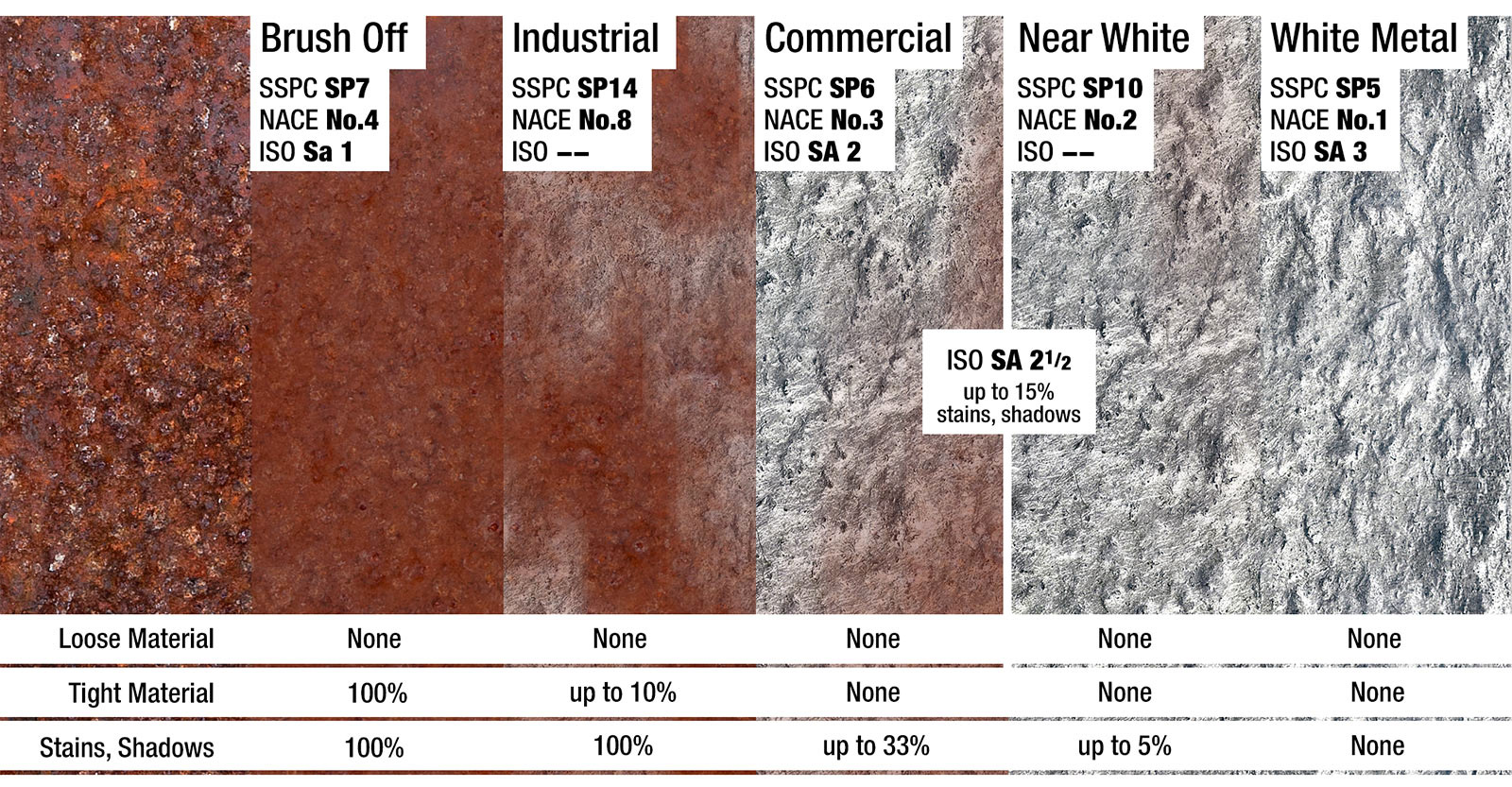

NACE SSPC-SP 5 Standard

Adherence to rigorous industry standards is essential to ensure consistently high-quality results. IPC scrupulously adheres to the NACE SSPC-SP 5 standard, commonly known as White Metal Blast Cleaning. This requirement guarantees the highest level of surface cleanliness and preparation, setting the stage for impeccable coating application and durability.

Garnet: Our Recommended Sandblasting Choice

Among the wide range of abrasives available, garnet is the preferred choice due to its unique properties

Hardness: Garnet’s unmatched hardness removes old coatings and impurities effectively without harming surfaces.

Abrasive: This allows surfaces to be prepared thoroughly, improving how well coatings stick.

Versatile: Garnet’s varied particle sizes allow for a wide range of uses, from heavy-duty removal to fine finishing.

Chemically Inert: This reduces the risk of reactions and ensures safety for both operators and surfaces.

Safer: Garnet’s low dust qualities mean a safer, cleaner work environment

Cost-Effect: Garnet aligns with IPC’s dedication to offering value without compromising quality.

Sandblasting Services: State-of-the-Art Dust Removal System

At IPC, our sandblasting facility boasts state-of-the-art dust collector systems. The sandblasting production line is completely separate from the coating spraying processes.

This advanced technology ensures a contamination-free environment, reducing the risk of coating contamination and protecting the integrity and quality of our products. Our commitment to environmental and operational excellence is reflected in the meticulous design and implementation of these modern systems.

Experienced Operators

Our sandblasting team relies on skilled operators, each with over a decade of experience in the industry.

Their deep knowledge combined with an unwavering commitment to quality ensures that each sandblasted surface receives meticulous attention and precision processing.

Their dedication to excellence shows how IPC is committed to delivering great results, making them crucial to our team and our customers’ project success.

Long Pipe Handling

The IPC facility is equipped to handle long pipe lengths, accommodating components up to 35 feet in length. With these extensive capabilities, we are able to meet a variety of design requirements with efficiency and precision.

Whether processing long pipes or other large-scale materials, customers can trust IPC to provide comprehensive sandblasting services tailored to their specific needs.

Curious About Our Superior Sandblasting Services

At IPC, our sandblasting process embodies our unwavering commitment to quality and customer satisfaction.

Through a synergistic combination of cutting-edge technology, experienced specialists and meticulous attention to detail, we ensure that every surface is primed to ensure optimal coating performance.

Customers can trust IPC as their partner of choice for unmatched excellence in surface preparation and coating solutions, affirming our industry leadership.

To learn more about our sandblasting process or how we might support your next project, call +1 800-856-4959 or contact us online here.