IPC 9000 Series is a game-changer in protective coatings, designed especially for the demanding needs of the oil and gas sector.

This thermal inter-diffused treatment is the new industry standard, delivering remarkable resistance against corrosion and erosion, even under highly elevated temperatures.

Traditionally, electroless nickel high phosphorous deposits have been relied on for their excellent barrier protection in corrosive environments.

However, with IPC setting an even higher standard thanks to the superior protection it offers, oil and gas companies are now choosing this superior coating for their operations.

IPC 9000 Series Benefits

Corrosion Resistance

This thermally inter-diffused electroless nickel coating displays remarkable chemical compatibility. This makes it great at withstanding a variety of aggressive substances often found in oil, gas, or geothermal environments.

Biggest Takeaway: IPC 9000 Series incorporates a multi-layered metallic alloy structure that forms three additional barrier layers, fortifying it against highly corrosive elements like H2S, CO2, or chlorides.

Erosion Resistance

One of the characteristic features of this coating is its exceptional resistance to erosion. It has also been thoroughly tested and proven to be exceptionally strong against erosive forces.

IPC Series 9000’s special structure and thermal treatment make it tough, helping it fight off abrasive particles and turbulent fluid flows often found in oil and gas work.

Biggest Takeaway: IPC Series 900 offers outstanding erosion protection which makes equipment and structures last longer, cutting down on maintenance and replacement expenses by a significant amount.

Surface Uniformity

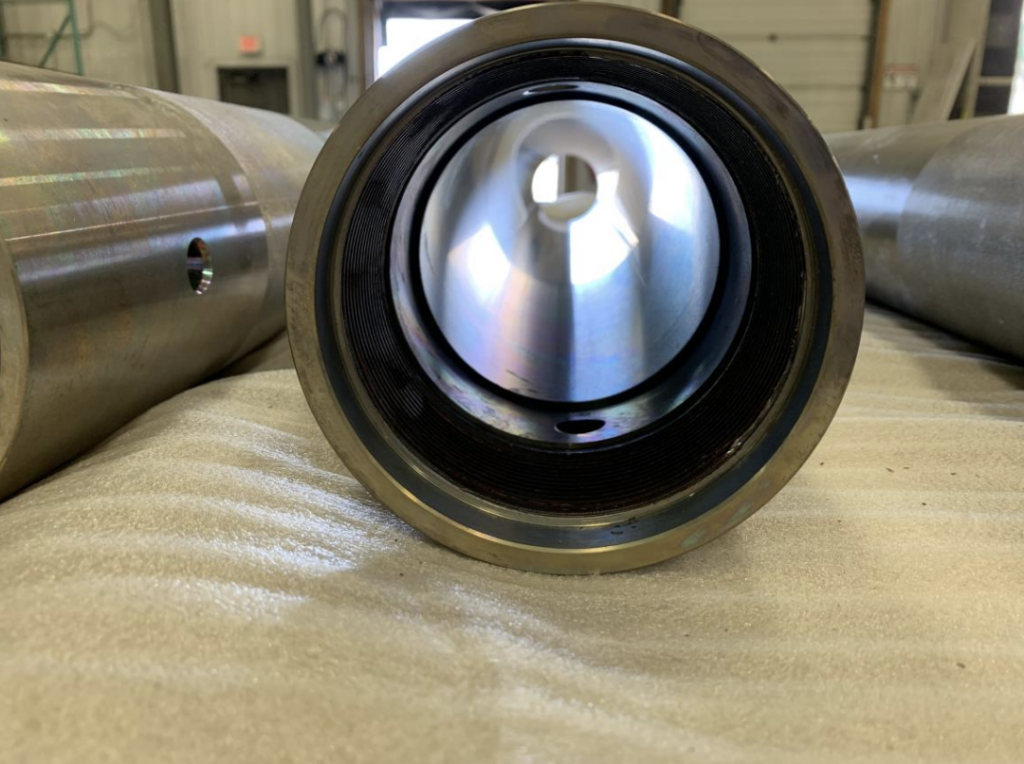

IPC Series 9000’s electroless deposition process ensures exceptional uniformity over complex shapes and surfaces. This allows it to provide consistent protection across intricate components commonly found in oil, gas, or geothermal equipment.

Biggest Takeaway: This uniformity of IPC Series 9000 helps maintain performance and reliability across diverse structures and configurations.

Adherence and Bond Strength

Another reason oil and gas companies love IPC Series 9000?

Its inter-diffused structure enhances its adherence and bond strength to substrates (mitigating the risk of delamination or peeling).

This robust adhesion is crucial in environments subjected to mechanical stresses, vibrations, and thermal cycling.

Biggest Takeaway: The adhesion bond strength of IPC Series 9000 is far more reliable than plated coatings alone.

Thermal Stability

IPC Series 9000 exceeds industry standards to provide exceptional performance in high-temperature environments.

Its thermally interdiffusion-treated nickel structure maintains integrity and functionality at extremely high temperatures, providing lasting protection against corrosion and erosion. This unique feature enables equipment and components to operate reliably in harsh environments, maintaining performance and safety while minimizing downtime and operational disruptions.

Biggest Takeaway: IPC Series 9000’s ability to withstand and perform well at high temperatures makes it an indispensable asset in oil and gas applications, increasing both the reliability and durability of your operation.

Tailored Applications

The versatility of IPC Series 9000 allows for customization to suit specific application needs.

Modifications in composition, coating thickness or inter-diffusing cycle can be made to enhance certain properties such as hardness, wear and corrosion resistance, or lubricity. This helps us cater to diverse requirements within the oil, gas, or geothermal sectors.

Biggest Takeaway: IPC Series 9000 is extremely versatile and can be made to suit the needs of different companies and projects around the world.

Environmental Considerations

IPC Series 9000’s durability and resistance to corrosion and erosion contribute to prolonged equipment life, reducing the need for frequent replacements.

This not only lowers maintenance costs but also aligns with sustainability goals by minimizing material wastage and reducing the environmental impact associated with frequent equipment replacements.

Biggest Takeaway: IPC Series 9000 helps you save thousands of dollars in maintenance costs while at the same time improving your carbon footprint.

Also Read: IPC Quality Control Sets Us Apart

What Equipment Can You Coat with IPC 9000 Series?

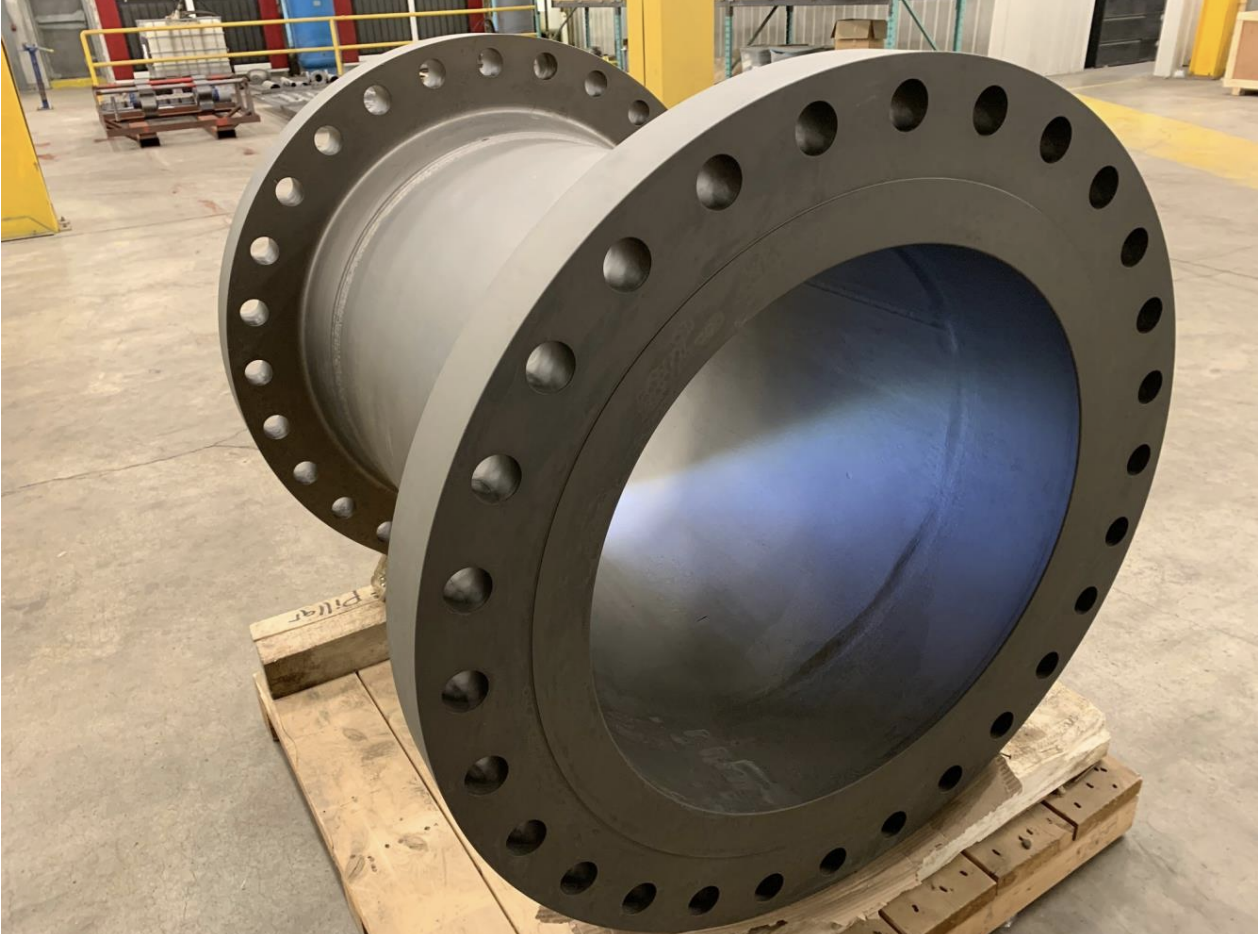

This inter-diffused nickel barrier coating is a versatile solution for safeguarding many critical components within the oil and gas industry.

Valves, fittings, couplings, collars, and wellhead equipment benefit from this protective coating, ensuring extended durability and resilience in harsh operating conditions.

Downhole tools, packer components, pumps and compressors find enhanced longevity and performance with this coating, mitigating wear and corrosion.

Tanks, vessels, housings, and piping spools also benefit, as the coating provides a robust shield against corrosive elements, thereby extending the lifespan of these essential structures.

Interested in IPC 9000 Series For Your Next Project?

Our advanced coating technology plays a pivotal role in preserving the integrity and reliability of various oil and gas companies around the world.

If you have questions about protective coatings or the products we offer, contact our sales team online here or give us a call at +1 800-856-4959.