IPC System 5 is an industry-leading multi-coat system of Teflon PFA formulated to provide superior chemical and permeation resistance in some of the most severe environments in the world.

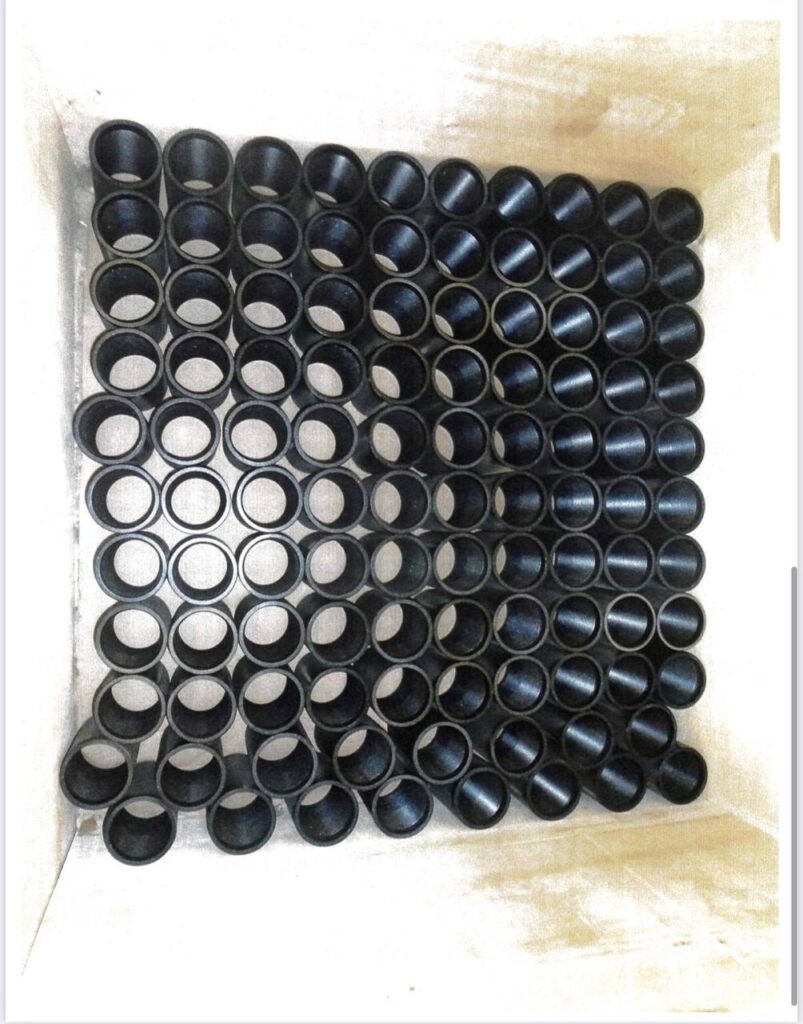

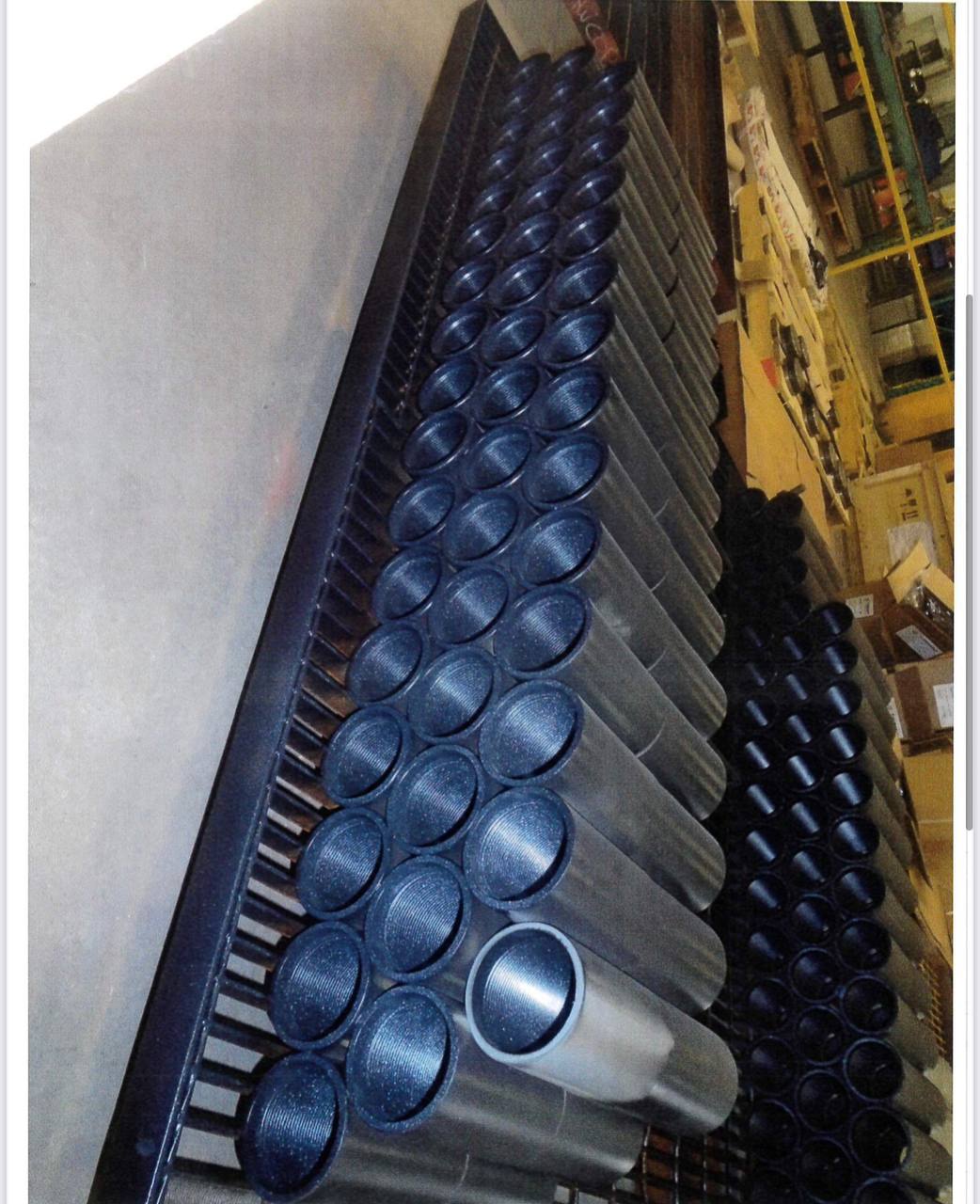

It has been successfully applied to a wide variety of oil and gas production equipment components including valves, fittings, pipe spools, downhole complete tools, sucker rods and more.

The Benefits of Our Teflon PFA Coating – Temperature Resistant, Creep Resistant and Chemical Resistant

IPC System 5 is a tested and proven coating that has been used in various applications including injection wells, brine service, etc. in some of the most corrosive conditions and environments around the world. It offers superior chemical resistance and the ultimate in corrosion and permeation protection.

Superior Corrosion and Permeation Protection

IPC System 5 offers superior permeation protection, helping your materials maintain structural integrity for years to come.

Designed to Withstand Vapour Permeation

IPC System 5 provides a strong permeation barrier against gases and liquids commonly used in industrial and oil and gas applications.

Excellent Thermal Stability

The industry-leading multi-coat system of Teflon PFA provides higher continuous-use temperatures (260 °C [500 °F]) than alternative coating options.

Superior Chemical Resistance

IPC Coatings have become synonymous with chemical resistance, offering the highest levels of protection against a variety of harmful chemicals.

Good Abrasion Resistance

IPC System 5 has the ability to withstand the wear and tear of friction often seen in most oil and gas systems.

High Film Build

Teflon PFA is thermoplastic and builds up significantly thicker than other fluoropolymers. This offers greater toughness than similar industry coatings.

Creep Resistance

IPC System 5 resists stress cracking and attack by almost all known chemicals and corrosive solvents.

Highly Temperature Resistant

This makes IPC System 5 highly adaptable and ideal for use in both high and low-temperature environments.

Also Read: Understanding The Differences Between PFA and PTFA

In addition to the numerous benefits mentioned above, IPC System 5 has become one of the best fluoropolymer coating products available on the market today thanks to our rigorous and proven application methods. IPC System 5 has the ability to build up to 20 mils, can coat complex shapes, offers a nonporous film and has a long and successful history in a wide variety of corrosive environments.

The IPC Coating Process

There are many reasons why IPC has been trusted by thousands of businesses around the world. One of the biggest is our tried and proven coating process.

Perfected over the last 43 years, our process focuses on both quality control and delivering the highest quality results possible for our customers.

#1 Evaluate — our team of professional engineering advisors reviews your specific application needs and uses their industry expertise to recommend the appropriate protective coating for your needs.

#2 Surface Preparation — unlike many of our competitors, our coating technicians are AMPP Certified which means when preparing your materials for coating, they adhere to strict industry standards to ensure everything is done correctly.

#3 Coating Process — after we have prepared your materials for coating, we coat them in a separate facility to eliminate the risk of microparticles interfering with the application. Our team maintains diligent records at every stage of the coating process. Once we achieve the desired result, we get your products ready for shipment.

#4 Delivery — our team works quickly and efficiently to ensure your project stays on track and you receive your materials on time.

#5 Follow-Up — Once you have received your order, we follow up to make sure they are living up to our industry-recognized reputation for high-quality results.

Also Read: The Best Protective Coatings For Wellheads in Canada

Interested in IPC System 5 (Teflon PFA) For Your Next Project?

Does your project require a coating strong enough to withstand a highly corrosive and temperature-variable environment? Our IPC fluoropolymer coatings have been used in a wide variety of markets. They are available in a full range of powder and liquid forms. They also come in different colours and allow for nearly unlimited applications.

IPC is capable of coating parts up to 20’ long X 6’ wide and 6’ high. Parts outside this dimension can be dealt with on a case-by-case basis. To learn more about our various fluoropolymer coating products or IPC System 5, click here.